In an era where precision, speed, and data-driven insights dominate project execution, EPC companies are adopting 3D Digital Twins for project lifecycle management to gain a strategic advantage. This transformative approach is rapidly gaining traction across industries such as Oil & Gas, Utilities, Manufacturing, Real Estate & Construction, Marine & Ports, Healthcare & Lifesciences, Banking, Minerals & Metals, Government Entities, Defense, Engineering, Procurement, and Construction (EPC), and Aviation, especially in dynamic regions like India, the GCC, and the Far East.

What is a 3D Digital Twin in Project Lifecycle Management?

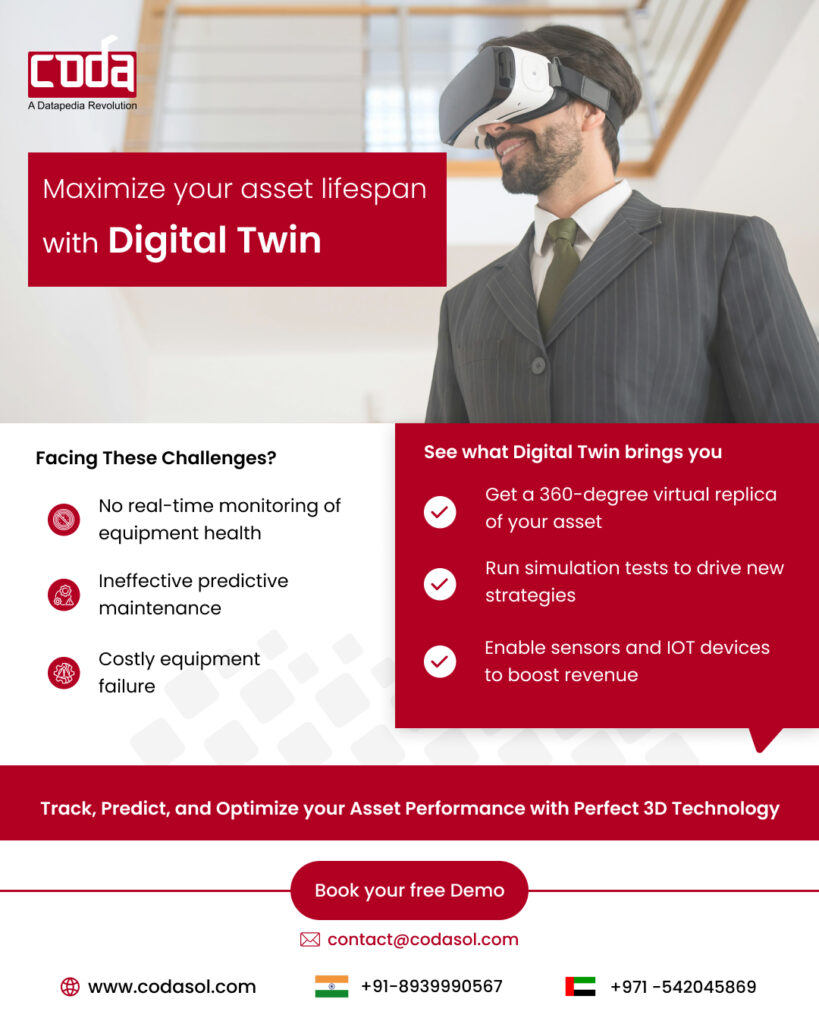

A 3D Digital Twin is a dynamic, virtual representation of a physical asset, infrastructure, or entire project environment. It is updated in real-time through data captured by sensors, IoT devices, drones, and software systems. By mirroring the physical project’s lifecycle stages — from design and engineering to construction, operation, and maintenance — 3D Digital Twins empower EPC companies to optimize decision-making, reduce risk, enhance collaboration, and increase asset reliability.

Key Benefits Driving Adoption of 3D Digital Twins by EPC Companies

| Benefit | Impact on EPC Companies |

|---|---|

| Real-Time Project Visibility | Monitor every phase of the project remotely and proactively manage risks. |

| Enhanced Collaboration | Integrate multidisciplinary teams, vendors, and stakeholders in a unified platform. |

| Cost and Time Savings | Identify issues early, reduce rework, and accelerate project timelines. |

| Predictive Maintenance and Operation | Anticipate failures before they occur, ensuring asset longevity and performance. |

| Regulatory Compliance and Reporting | Maintain an auditable, compliant record for government entities and clients. |

Why the Shift is Happening Now

Several factors are accelerating the move towards 3D Digital Twins for project lifecycle management:

- Increased Complexity of Mega Projects: Projects in Oil & Gas, Aviation, and Construction now span multiple countries and regulatory bodies.

- Need for Remote Monitoring: Especially after the pandemic, remote management has become a must.

- Integration of IoT and Smart Technologies: Availability of real-time data streams enhances the value of digital twins.

- Pressure to Deliver on Time and Budget: Shrinking margins in EPC contracts require higher efficiency.

- Mandates for Sustainability: Governments in the GCC and Far East are pushing for more sustainable, data-driven project execution.

Top Use Cases for 3D Digital Twins in EPC Industries

- Oil & Gas: Simulate refinery operations, detect pipeline issues, optimize maintenance.

- Utilities: Digitally manage large-scale infrastructure like grids, substations, and power plants.

- Construction & Real Estate: Visualize entire smart cities, construction progress, or building maintenance.

- Marine & Ports: Simulate port operations, optimize ship maintenance and berthing operations.

- Healthcare & Lifesciences: Manage hospital construction and maintenance projects with zero downtime.

- Banking: Manage massive infrastructure projects like headquarters or data centers.

- Defense: Simulate and plan base construction, airfield upgrades, and maintenance.

- Government Entities: Streamline urban development and national infrastructure projects.

Ready to transform your EPC project management with 3D Digital Twins? Book a personalized demo with our experts today!

How 3D Digital Twins Transform Each Stage of the Project Lifecycle

| Project Stage | 3D Digital Twin Advantage |

|---|---|

| Planning and Design | Visualize end-to-end layouts, detect design clashes early, run simulations. |

| Procurement | Track materials digitally, optimize inventory and delivery schedules. |

| Construction | Monitor progress against design in real-time, enhance safety management. |

| Commissioning and Handover | Create a digital archive for operations teams, reducing onboarding time. |

| Operations and Maintenance | Enable predictive maintenance, minimize downtime, optimize asset performance. |

| Decommissioning | Plan safe and cost-effective decommissioning based on historical data models. |

Regional Insights: India, GCC, and Far East

- India: Driven by initiatives like “Digital India” and rapid urbanization, demand for 3D Digital Twins for EPC companies is surging.

- GCC Countries: Vision 2030 initiatives in Saudi Arabia and major infrastructure investments across UAE, Qatar, and Oman are fueling adoption.

- Far East: Countries like Singapore, South Korea, and Japan are leading smart city projects where 3D Digital Twins are critical.

Frequently Asked Questions (FAQs)

1. What are the challenges EPC companies face when adopting 3D Digital Twins?

Adoption challenges include upfront investment costs, integration with legacy systems, and change management for personnel used to traditional methods.

2. Can small to medium-sized EPC companies benefit from 3D Digital Twins?

Absolutely. With the emergence of SaaS-based and cloud-hosted solutions, even mid-sized EPC firms can leverage 3D Digital Twins for project lifecycle management without large capital investments.

3. What technologies power 3D Digital Twins?

Technologies include IoT, cloud computing, AI/ML, advanced analytics, Building Information Modeling (BIM), and Geographic Information Systems (GIS).

4. How does a 3D Digital Twin improve project sustainability?

By reducing material waste, improving energy efficiency, and optimizing operational processes, 3D Digital Twins contribute to greener project outcomes.

5. Are 3D Digital Twins only for new projects?

No. They are increasingly being used to retrofit, renovate, or manage existing assets more efficiently by creating digital versions of physical structures.

Ready to see how a 3D Digital Twin can transform your next EPC project?

Book a 30-minute strategy session with our experts to explore custom use cases, ROI insights, and an implementation roadmap.