Are You Really Happy with All of Your Material Types?

Across Oil & Gas, Petrochemicals, Fertilizers, Utilities, Steel, and Cement industries, the largest portion of material data isn’t found in finished goods. It lives in indirect or non-production items, such as:

- MRO (Maintenance, Repair, and Operations) Spare Parts

- Production Consumables

- Safety Equipment and Tools

- Office Supplies

- Miscellaneous “Other” Items

These materials may not be tied directly to production outputs, but they impact everything from inventory holding costs to equipment uptime and procurement efficiency.

Most of this data is scattered, inconsistent, duplicated, and misclassified across plants.

The Hidden Risk in Your ERP Data Strategy

When organizations implement ERP systems like SAP, Oracle, or Maximo, their material master data strategy often begins with the most obvious targets:

- Finished Products

- Packaging

- Raw Materials

These materials are closely tied to revenue, making them the obvious “low-hanging fruit.” As a result, most data quality projects stop after optimizing these 2,000–3,000 SKUs.

Is that really where your greatest value lies?

For most enterprises, especially in asset-heavy industries, the biggest opportunity is buried deeper in the long tail of data.

The Long Tail Problem:

Once the “core” SKUs are cleaned, many businesses halt further cleansing efforts.

Why?

- Cleansing gets harder further down the list.

- Tools aren’t built to handle scale and complexity.

- ROI feels less tangible

The reality?

The long tail of your material master is silently inflating your costs through:

- Excess inventory

- Maverick buying

- Stockouts

- Duplicate purchases

- Delayed maintenance and downtime

If you don’t tackle the long tail, you’re leaving massive value on the table.

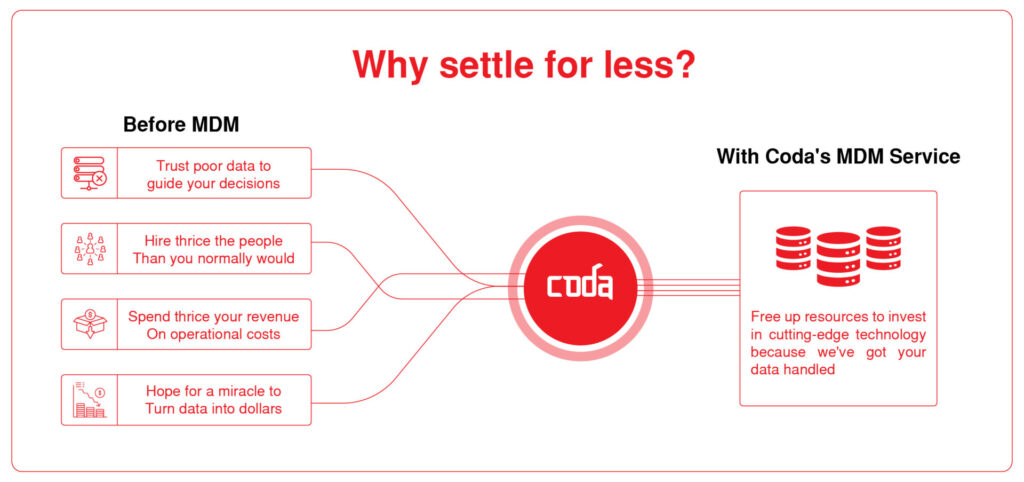

Stop settling for surface-level data cleanup. Discover how CODASOL can optimize your entire material, from spare parts to safety gear.

The CODASOL Edge in Indirect Material Master Data Management

CODASOL’s AI/ML-powered material master data management platform is purpose-built to handle the complexity of indirect materials, not just the easy, obvious ones.

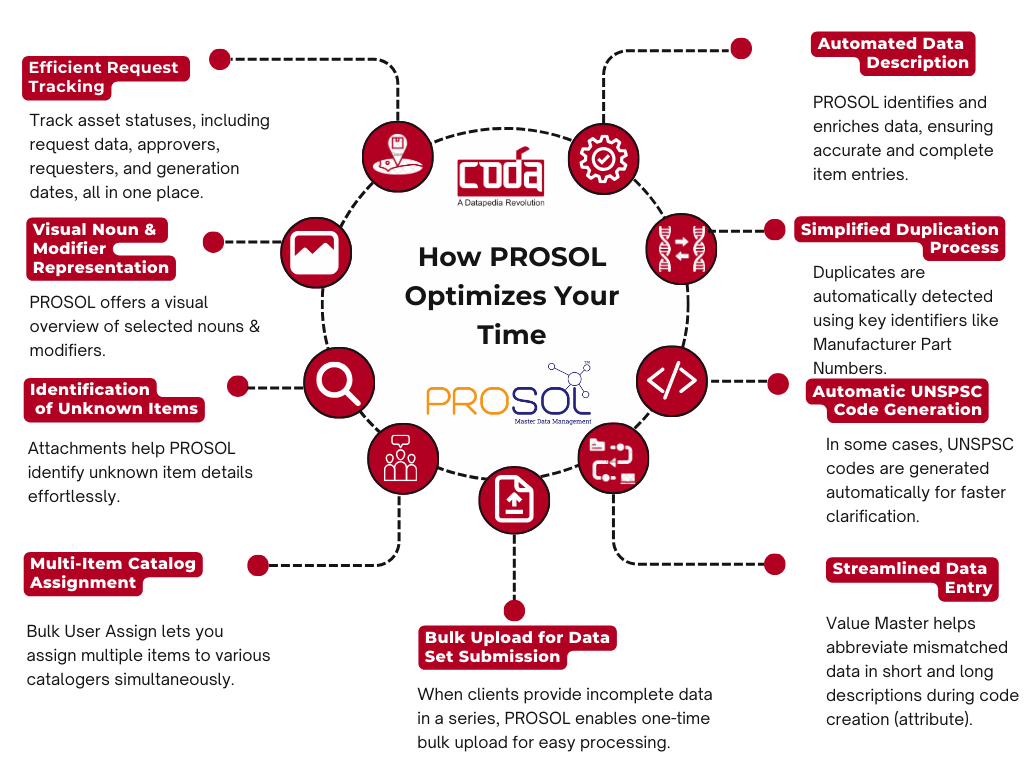

Key Capabilities:

1. AI-Powered Material Classification

Automatically classifies indirect materials across SAP, Oracle, and Maximo using standards like ISO 8000, UNSPSC, eCl@ss, and ECCMA.

2. Contextual De-Duplication

Our logic-based algorithms detect and eliminate duplicates, even across different languages, synonyms, abbreviations, and misspellings.

3. Standardized, SAP-Compliant Descriptions

Legacy material descriptions are cleansed and rewritten to follow SAP naming conventions, improving readability and eliminating confusion.

4. Localization Support

Clean and normalize material data across geographies, systems, and user contexts.

5. Real-Time Spend & Inventory Analysis

Gain visibility into spend patterns, supplier overlaps, and overstock situations through advanced data tagging and segmentation.

6. Pre-Built Integration

No custom development needed. Delivered with LSMW-ready maps, plug-and-play ERP integration, and pre-configured workflows.

What Our Clients Achieve

Across CODASOL’s client projects, these are the average results driven by full-spectrum indirect material master data management:

| Benefit Area | Typical Savings |

| Inventory Cost Reduction | 8–12% |

| Procurement Cost Reduction | 10–15% |

| Equipment Downtime Reduction | 2–5% |

| Storage & Supply Chain Optimization | 3–5% |

| Worker Productivity Gains | 5% |

| Accounting/Compliance Risk Reduction | 3% |

These are not hypothetical numbers; they come from companies that dared to look beyond the first 3,000 materials.

Quick Wins with Indirect Material Master Optimization

- Fewer stockouts and less emergency procurement

- Lower working capital tied up in slow-moving or obsolete inventory

- Shared spares across plants, enhancing operational continuity

- Faster goods receipt and invoice matching

- Clean spend data enabling better sourcing and negotiations

- Improved compliance with international standards (ISO, ECCMA, eCl@ss)

- Centralized visibility into suppliers and material usage

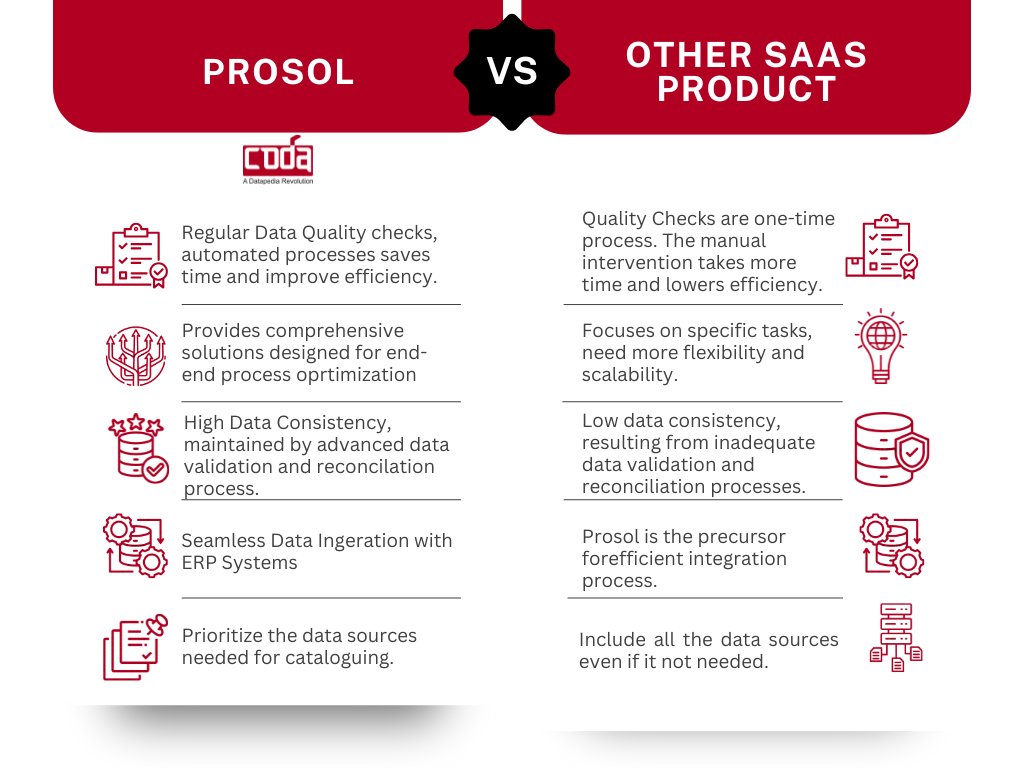

Why CODASOL Is the Industry’s First Choice

We’re not just a software provider. We’re domain experts in asset-intensive sectors with 10+ years of experience solving indirect material data challenges.

Here’s what makes us different:

- Proven frameworks built specifically for MRO and indirect materials

- AI/ML-driven solutions — no need for custom coding

- End-to-end support: From cleansing to governance

- ERP-ready outputs that drop seamlessly into SAP, Oracle, Maximo

- Scalable results across plants, business units, and geographies

Ready to Go Beyond Finished Goods?

You’ve cleansed your finished goods and packaging.

Now it’s time to unlock the hidden savings within your indirect materials.

CODASOL helps you surface that value quickly, intelligently, and without disrupting operations.

Let’s turn your material master from a liability into a strategic asset.

Frequently Asked Questions

1. What is indirect material master data management?

It refers to the process of cleansing, classifying, and managing non-production materials like spare parts, tools, and safety equipment in ERP systems.

2. Why do indirect materials matter in MDM?

Because they represent the largest volume of SKUs and are often unmanaged — leading to duplication, increased procurement costs, and operational delays.

3. How can AI improve indirect material data quality?

AI automates classification, eliminates duplicates, generates standard descriptions, and improves data governance across multiple systems.

Still Managing “Other” Materials the Old Way?

Start using our platform to classify, cleanse, and control your indirect materials without disrupting your ERP.