How Master Data Management (MDM) Drives Warehouse Optimization from the Ground Up

Warehouses are the nerve centers of asset-intensive industries. But without master data management warehouse optimization, even the most advanced facility runs into chaos like stockouts, duplicated inventory, mis-shipped items, and unnecessary costs. For decision-makers in Oil & Gas, Manufacturing, Utilities, and other complex sectors, the question isn’t whether to optimize warehouses, but how. That’s where Master Data Management (MDM) steps in, transforming warehouse operations from a patchwork of spreadsheets into a streamlined, intelligence-driven system.

This post unpacks how MDM drives warehouse optimization from the ground up, giving you a blueprint for better accuracy, traceability, and profitability.

Why Warehouses Struggle Without MDM

Picture this: A global manufacturing firm runs multiple warehouses across India, Saudi Arabia, and the US. Each site maintains its own records for spare parts, materials, and vendors. A valve in one warehouse is listed as “Valve-01,” in another as “Steel Valve 1,” and in a third as “Industrial Valve.” They’re the same part, but the system treats them as three different items.

This will cause:

Redundant purchases, inflated stock levels, longer cycle counts, and missed savings opportunities.

Data silos like this are the single biggest reason warehouses bleed efficiency. Without a central source of truth, operations are reactive, not strategic.

Enter Master Data Management: The Single Source of Truth

Master Data Management (MDM) consolidates, cleanses, and standardizes data across all warehouse systems. It creates a “golden record” for every material, supplier, customer, and asset—removing duplicates, fixing inconsistencies, and ensuring that everyone sees the same information across ERPs, procurement tools, and warehouse management systems (WMS).

Instead of guessing whether “Valve-01” and “Industrial Valve” are duplicates, the system knows they’re identical. Instead of manually reconciling stock reports, decision-makers get real-time insights on inventory health.

With MDM, warehouses shift from firefighting mode to a predictive, optimized operation.

5 Ways MDM Optimizes Warehouse Performance

1. Accurate Inventory Levels

When every item is standardized, stock counts reflect reality. No more “phantom stock” that exists in records but not in racks. This reduces carrying costs and ensures critical spare parts are always available when needed.

2. Faster Order Fulfillment

Clear, consistent product data helps pickers locate the right items without second-guessing. A well-structured catalog speeds up warehouse operations, reducing lead times and improving customer satisfaction.

3. Streamlined Procurement

With unified master data, procurement teams see exactly what’s in stock across multiple locations. This prevents duplicate purchases, enables bulk buying, and strengthens supplier negotiations.

4. Better Traceability & Compliance

In industries like Oil & Gas and Healthcare, regulatory compliance requires clear documentation of every item’s origin, movement, and usage. MDM ensures traceability from supplier to warehouse to end-use, reducing audit risks.

5. Smarter Planning & Forecasting

Clean data is the foundation of AI and advanced analytics. With MDM in place, predictive algorithms can forecast demand, optimize reorder points, and even recommend warehouse layouts for maximum efficiency.

Tired of carrying excess stock and losing money to data chaos? Let us deliver warehouse-ready data management to help you reclaim efficiency.

Comparing Warehouses With and Without MDM

| Factor | Without MDM | With MDM |

|---|---|---|

| Inventory Accuracy | 60–70% | 95%+ |

| Duplicate Stock Levels | High | Minimal |

| Order Fulfillment Speed | Slow, error-prone | Fast, reliable |

| Procurement Costs | Inflated by redundant purchases | Reduced through visibility |

| Compliance Readiness | Manual, time-consuming | Automated, audit-ready |

Case Study

An EPC (Engineering, Procurement, and Construction) company in the GCC was struggling with material duplication across multiple warehouses. The same spare part was recorded under 15 different names, leading to overstocking and millions in wasted procurement.

After implementing MDM, the company consolidated its material master, reduced duplicate entries by 80%, and cut procurement costs by 20%. Warehouse staff reported faster picking times, and auditors praised the improved traceability.

The ROI of Warehouse-Centric MDM

Investing in MDM pays off in measurable terms:

- 20–30% reduction in inventory carrying costs

- 15–20% improvement in order fulfilment speed

- Up to 50% reduction in duplicate procurement

- Audit readiness in days instead of months

For asset-intensive industries, these savings can translate into millions annually.

How to Start: Building a Warehouse MDM Strategy

- Assess Current Data Quality

Conduct a data audit to identify duplicates, inconsistencies, and gaps. - Define Data Standards

Establish naming conventions, classification rules, and governance policies. - Choose the Right MDM Platform

Opt for a solution that integrates with your ERP, WMS, and procurement systems. - Cleanse and Consolidate Data

Deduplicate, enrich, and validate records before creating the golden record. - Train and Onboard Teams

Change management is critical. Ensure warehouse staff understand and adopt the new standards. - Monitor and Improve Continuously

Data governance is ongoing. Establish KPIs for accuracy, duplication, and compliance.

If your warehouses are drowning in duplicate materials, inconsistent part codes, and audit headaches, it’s time to rethink your strategy.

Why MDM Matters for Your Region

- India & GCC: MDM supports large-scale industrial growth where multiple ERPs and supply chains must align across sites.

- Far East: High-volume manufacturing relies on precise material traceability—MDM makes it possible.

- US: With strict compliance in Healthcare, Aerospace, and Defense, MDM ensures warehouses stay audit-ready while improving margins.

MDM isn’t a back-office function; it’s a front-line enabler of warehouse efficiency, profitability, and resilience.

Frequently Asked Questions

1. What is Master Data Management in warehouses?

MDM standardizes and consolidates material, supplier, and customer data to create a single source of truth, enabling efficient warehouse operations.

2. How does MDM improve inventory accuracy?

By eliminating duplicates and inconsistencies, MDM ensures that recorded stock matches actual physical inventory.

3. Can MDM integrate with existing ERP and WMS systems?

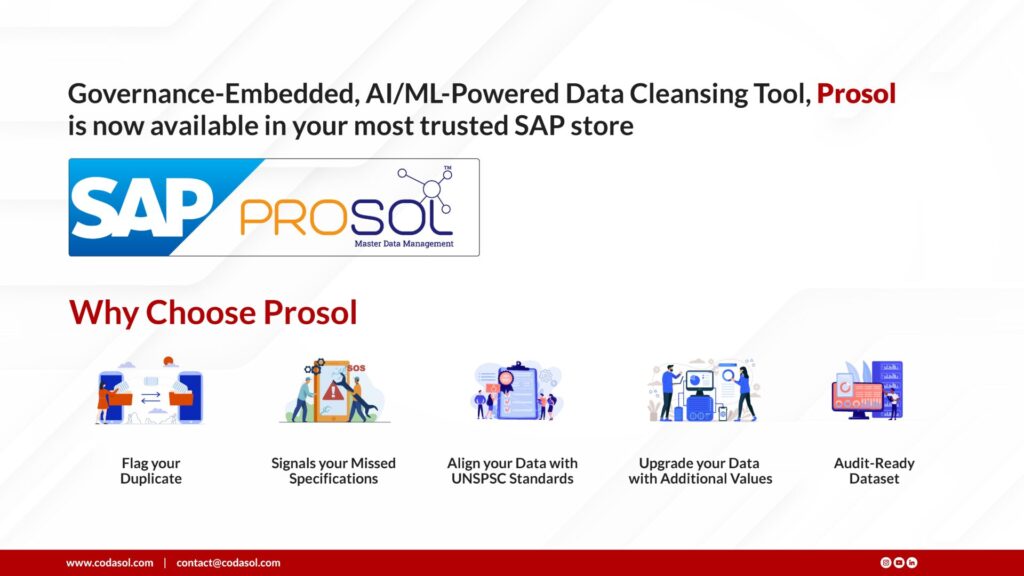

Yes. Modern MDM platforms like PROSOL integrate seamlessly with SAP, Oracle, Maximo, and other leading systems.

4. What industries benefit most from warehouse MDM?

Industries with complex supply chains, Oil & Gas, Manufacturing, Healthcare, Utilities, and EPC, see the highest ROI.

5. How fast can companies see results from MDM?

With the right platform, many organizations see efficiency gains within 3–6 months of implementation.

Ready to take the next step? PROSOL is now available in the SAP Store, making it easier than ever to integrate world-class Master Data Management directly into your existing SAP ecosystem.