How to Use Material Master Enhancement to Boost Efficiency in SAP & Oracle

Material Master Enhancement can transform the way your business operates. In SAP and Oracle systems, every procurement order, production plan, and inventory decision depends on accurate material data. When this data is inconsistent, duplicated, or outdated, it creates delays, drives up costs, and increases the risk of compliance issues.

For decision-makers in industrial and asset-intensive industries, enhancing the material master is about more than just fixing data; it’s the process of upgrading, cleansing, and governing the core material data in your ERP system. When executed properly, it turns a liability into a competitive edge, reducing errors, enabling accurate reporting, and unlocking savings across procurement and operations. This article provides a practical, step-by-step approach to material master enhancement, highlighting best practices, tools, and governance strategies for SAP and Oracle systems.

What Is Material Master Enhancement?

The material master is the backbone of ERP systems like SAP and Oracle. It houses all the essential data required for procurement, production, sales, and compliance from material descriptions and classifications to pricing, weights, and technical specifications.

Enhancement goes beyond routine maintenance. It includes:

- Standardization: Aligning naming conventions, units of measure, and classifications.

- Data Cleansing: Identifying and removing duplicates, errors, or outdated records.

- Governance: Establishing rules, ownership, and workflows for ongoing control.

- Enrichment: Adding missing attributes to support analytics, compliance, and operations.

When organizations talk about “enhancing” their material master, they are not just cleaning data, they are creating a trusted foundation for digital transformation.

Why It Matters for Industrial Enterprises

Bad material data is expensive. Gartner estimates that poor data quality costs organizations an average of $12.9 million annually. In industries like oil & gas, utilities, and manufacturing, the stakes are even higher.

Examples:

- A Gulf-based oil company discovered that duplicate spare part codes inflated procurement costs by $2.6 million annually.

- A utilities firm reduced stockouts by 18% after enhancing its SAP material master.

- A manufacturing enterprise improved regulatory compliance reporting by 40% after enrichment and standardization.

These are not isolated wins. They highlight a systemic truth: material master enhancement drives efficiency, cost reduction, and compliance across the enterprise.

Core Challenges in Material Master Data

Despite ERP investments, most organizations struggle with the same issues:

- Duplicates & Inconsistencies – A single part may exist under different codes, descriptions, or units across plants.

- Legacy Data – Outdated entries from prior ERP systems or manual spreadsheets.

- Non-standard Fields – Different departments or geographies using different naming rules.

- No Governance – Lack of defined roles for who creates, approves, and maintains material data.

- ERP Migrations – Transitioning to SAP S/4HANA or upgrading Oracle ERPs often reveals hidden data chaos.

Best Practices for Material Master Enhancement

To overcome these challenges, enterprises can adopt a structured approach:

1. Establish Governance Framework

- Define ownership roles (data stewards, approvers, IT leads).

- Create approval workflows for new material creation.

- Set KPIs for data quality (accuracy, completeness, timeliness).

2. Standardize & Cleanse

- Develop templates with standard naming conventions.

- Normalize units of measure, material groups, and classifications.

- Deduplicate existing records using automated tools.

3. Use the Right Tools

- SAP: MM17 (mass change), Data Migration Cockpit, Data Services.

- Oracle: Item Master module, Item Lifecycle Management, bulk update tools.

- Third-party MDM platforms: for advanced cleansing, enrichment, AI-driven standardization.

4. Enrich Data for Value

- Add missing technical attributes (weight, dimensions, hazardous codes).

- Include sustainability or compliance attributes for ESG reporting.

- Capture supplier data for sourcing optimization.

5. Continuous Monitoring

- Build dashboards to track duplicates, incomplete fields, or delayed approvals.

- Audit regularly to sustain improvements.

Ready to see the gaps in your ERP data?

SAP vs Oracle:

| Feature | SAP (S/4HANA, ECC) | Oracle (EBS, Cloud ERP) | Third-Party MDM Solutions |

|---|---|---|---|

| Bulk Update Tools | MM17, Migration Cockpit | Item Master Mass Update | Yes (AI-driven) |

| Data Cleansing | Limited native | Limited native | Advanced rules, deduplication |

| Governance Workflows | Customization required | Configurable in ILM | Built-in approval workflows |

| Enrichment Capabilities | Manual or add-ons | Manual or add-ons | Automated enrichment options |

| Scalability Across ERPs | SAP-only | Oracle-only | Multi-ERP integration |

This comparison shows why many organizations use ERP tools for tactical updates, but deploy MDM solutions for strategic, enterprise-wide enhancement.

ROI & Risk Mitigation

The ROI of material master enhancement is straightforward:

- Savings: Eliminate duplicate SKUs (procurement cost reduction of 5–10%).

- Efficiency: Reduce material creation cycle times by up to 40%.

- Compliance: Avoid fines by ensuring regulatory attributes are accurate.

- Inventory Optimization: Prevent overstocking and stockouts.

Risks include:

- Underestimating the scale of dirty data.

- Lack of cross-functional buy-in.

- Scope creep in large ERP migrations.

Mitigation involves phased rollouts, stakeholder engagement, and tool selection aligned with business goals.

Implementation Roadmap

- Audit Current Data – Assess duplicates, completeness, errors.

- Pilot a Plant or Business Unit – Run enhancement project on limited scope.

- Roll Out Enterprise-Wide – Scale processes, governance, and automation.

- Embed Continuous Improvement – Regular audits, KPIs, and training.

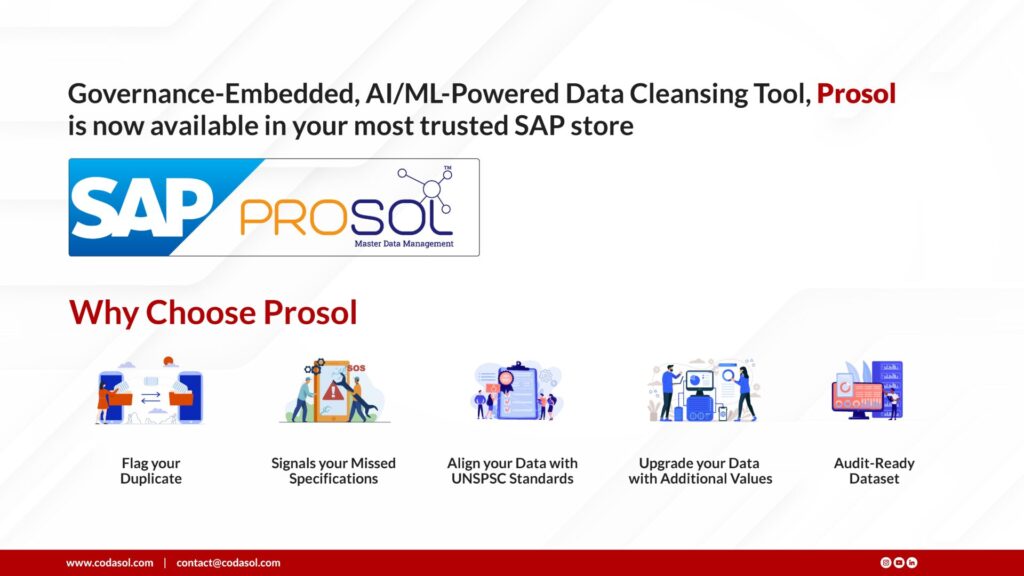

Why Prosol Is the Smarter Way to Enhance Material Masters

While SAP and Oracle offer native tools for bulk updates and limited cleansing, they were not designed to deliver end-to-end material master enhancement. This is where Prosol, CODASOL’s flagship cloud-based MDM and governance platform, fills the gap.

Prosol Ecosystem Capabilities:

- i-Stock – Advanced asset tagging, material verification, and conditional auditing to validate physical stock against ERP records.

- ProPedia – An AI-powered catalogue library that ensures standardized, enriched material descriptions with duplicate elimination.

- Infony – A machine learning engine for data extraction, anomaly detection, and health checks, enabling proactive data governance.

- Prosol Swift – ERP-ready data at speed:

- 50% faster ERP data readiness

- 98% compliance with international standards from day one

- Multi-million-dollar sourcing savings through duplicate elimination

- 40% quicker material creation cycle

- $180K recovered in excess inventory

Why Prosol Stands Out:

Unlike generic ERP tools, Prosol integrates governance, automation, and AI-driven enrichment. It not only enhances your current material master but also ensures ongoing compliance, accuracy, and cost optimization.

Explore how Prosol can standardize and enrich your SAP & Oracle material masters.

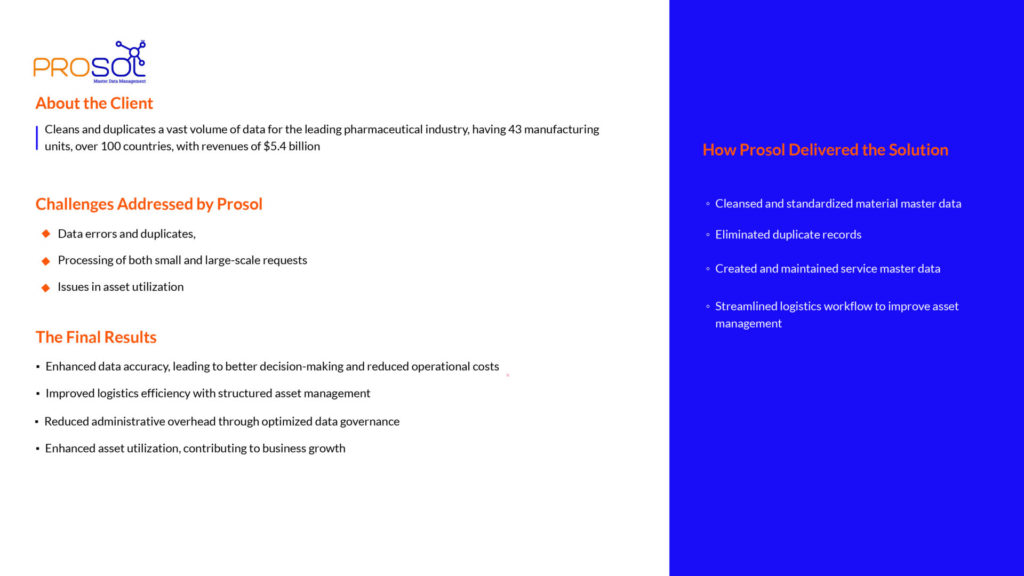

Case Example:

A Middle East oil company managing multiple plants faced duplicate spare parts across SAP and Oracle. After a structured enhancement project:

- 98% standardization across plants

- $2.6 million savings from duplicate SKU consolidation

- 40% faster material creation cycle

- Improved sourcing decisions through enriched supplier attributes

This demonstrates the scale of impact possible in asset-intensive industries.

Conclusion

Material master enhancement is not a “nice-to-have.” It is a strategic necessity for organizations running SAP and Oracle. Clean, standardized, and enriched data ensures cost savings, efficiency, and compliance.

Frequently Asked Questions

1. What is material master enhancement?

It is the process of cleansing, standardizing, enriching, and governing material data in ERP systems like SAP and Oracle.

2. How often should material master data be audited?

At least annually, with continuous monitoring for high-impact attributes.

3. Can SAP and Oracle material masters be standardized together?

Yes, with MDM platforms that provide cross-ERP integration and standardization rules.

4. What are common KPIs for material master quality?

Completeness, duplicate rate, cycle time for material creation, and compliance attributes accuracy.

5. What tools help with material master enhancement?

SAP MM17, Oracle Item Master, and third-party MDM platforms for advanced governance.

6. What industries benefit most?

Asset-intensive sectors such as oil & gas, utilities, manufacturing, defense, and construction.

Discover how Prosol streamlines material master enhancement in SAP