What Bad Data Has to Do with Procurement Costs

You’re reviewing your latest procurement report, and something doesn’t sit right. Procurement costs are rising. Supplier delays are more frequent. Your team is stuck putting out fires instead of driving value.

What’s going wrong?

The answer may not be in the headlines or market trends; it could be right inside your ERP: bad data.

Across manufacturing hubs in India, refineries in the GCC, and logistics networks in Southeast Asia, procurement leaders are facing the same silent challenge. And too often, poor-quality supplier data is the unspoken driver behind rising costs, lost opportunities, and rising operational risk.

Procurement Cost Pressure Isn’t Just from the Market Anymore

Yes, global conditions are tough:

- Inflation and Supply Chain Disruptions have pushed up logistics and raw material costs.

- Evolving Regulations demand cleaner records and tighter compliance.

- Supplier Consolidation means you have less leverage in negotiations.

But there’s a bigger, often overlooked cost driver: your internal data hygiene. Even in stable conditions, poor supplier data can quietly drain your budget.

How Bad Data Quietly Wrecks Procurement Efficiency

1. Faulty Decisions from Faulty Data

Outdated records. Duplicate entries. Missing certifications.

When procurement teams act on inaccurate supplier data, they risk everything from sourcing non-compliant vendors to missing bulk discounts. The Harvard Business Review estimates bad data costs the U.S. economy $3 trillion annually. That’s not just a problem—it’s a crisis.

2. Process Bottlenecks and Wasted Time

Poor data creates friction everywhere. Staff spend hours manually validating vendor info, fixing invoice errors, or chasing approvals for incomplete records. According to Gartner, this inefficiency cuts productivity by up to 20%.

3. Compliance and Risk Exposure

Environmental, social, and governance (ESG) expectations are rising fast. If your supplier data is incomplete or incorrect, you may inadvertently violate regulatory requirements—leading to fines, lawsuits, or reputational damage.

4. Broken Supplier Relationships

Late payments, wrong POs, or compliance confusion erode trust. When vendors get burned, they deprioritize your orders—or worse, walk away. In volatile industries, those relationships are not easy to replace.

Oil & Gas Example:

Take the case of a UAE-based petrochemical company. Oil price volatility is already putting pressure on margins. But that’s only part of the story.

Due to outdated supplier data, like missing compliance certificates and incorrect payment details, procurement teams were forced into last-minute sourcing. Deliveries were delayed. Projects stalled. Costs skyrocketed.

A study found that a one-unit rise in oil price volatility can drive procurement costs up by $4 million. But when bad data adds fuel to the fire, the financial impact multiplies.

What Bad Data Really Costs You

| Impact Area | How Bad Data Hurts | Cost Implications |

|---|---|---|

| Decision-Making | Poor vendor choices, missed savings | Up to 15% higher spend |

| Operational Efficiency | Manual rework, delays | 20% productivity loss |

| Compliance | Regulatory violations, reputational damage | Fines, legal costs, brand erosion |

| Supplier Relationships | Missed SLAs, low trust, lost partners | Long-term supplier churn risk |

Ready to Take Control?

If you suspect bad data is driving up your procurement costs, don’t wait for the next crisis. Start with a supplier data audit and explore automation tools tailored for your industry.

Get our Procurement Data Audit Checklist and identify hidden cost drivers in your current system.

Turning the Ship Around: How to Rein In Rising Procurement Costs

It’s not all doom and gloom. You can reverse this trend, and it starts with your data.

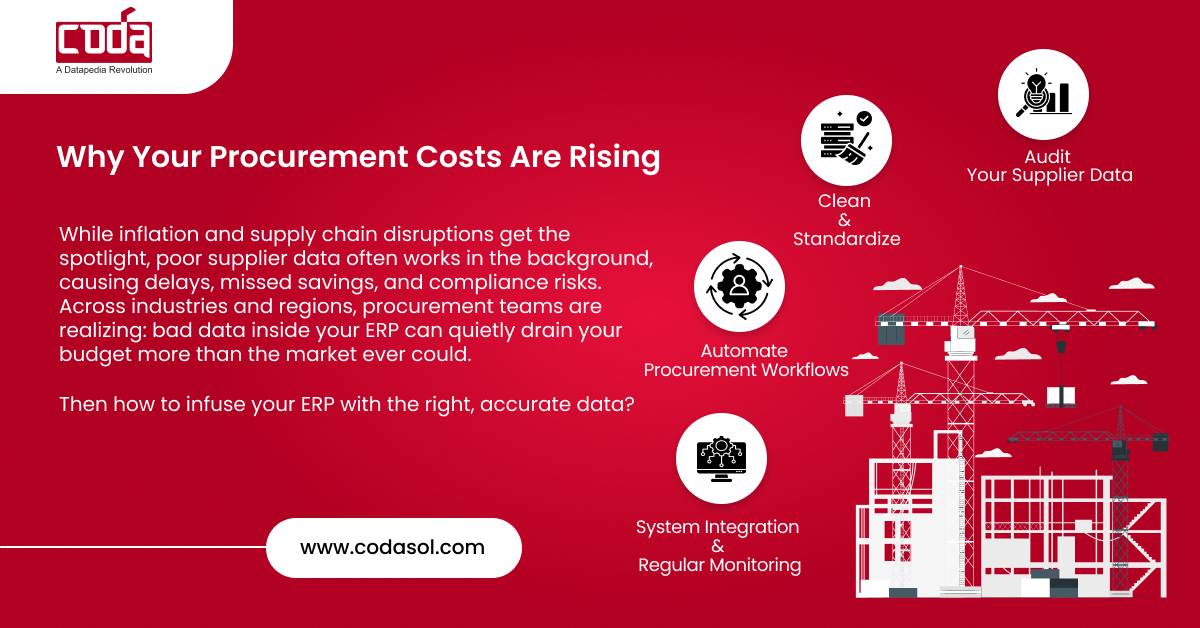

1. Audit Your Supplier Data

Start with a health check. Look for missing fields, outdated entries, duplicate vendors. If you can’t trust your data, nothing else matters.

2. Clean and Standardize

Use standardized templates for onboarding. Cleanse data regularly, deactivate dormant vendors, update key fields, and enforce naming conventions.

3. Automate Procurement Workflows

Adopt automation tools for purchase orders, approvals, and supplier communication. Less human intervention means fewer errors and faster cycles.

4. Integrate Your Systems

Break down silos between procurement, finance, and compliance. Integrated data means a unified view of supplier performance and risk.

5. Monitor Continuously

Set KPIs to track data quality, like error rates, update frequency, and supplier response times. Clean data isn’t a one-time fix; it’s an ongoing discipline.

Use Case:

A large Indian manufacturing company faced skyrocketing procurement costs and frequent stockouts. A data audit showed that 30% of supplier records were outdated or incomplete.

They implemented an automated onboarding system and scheduled quarterly data cleanups. Within six months:

- Procurement processing costs dropped 25%

- Supplier disputes were cut in half

- Sourcing cycle times improved by 40%

Frequently Asked Questions

1: My procurement team is overwhelmed. Where should we start?

Start with a focused data audit. Identify and prioritize your top 100 suppliers and get their records right first.

2: Does this apply to oil & gas or manufacturing specifically?

Yes. These sectors rely on precision, tight timelines, and compliance. Poor data in these environments is a fast path to high costs and risk.

3: What ROI can I expect from automation and data cleanup?

Most companies report 25–30% reduction in processing costs, improved supplier response times, and faster time-to-order.

4: How often should we cleanse supplier data?

Quarterly is ideal. For fast-moving industries, monthly reviews may be necessary.

5: We’re a small team. Is automation worth it for us?

Yes. Even small-scale automation, like digital supplier forms, can eliminate repetitive tasks and prevent costly errors.

Final Word:

Procurement Costs Are a Data Problem. Fix That First. Rising procurement costs aren’t just about market forces. Inaccurate, incomplete, or disorganized data is a hidden but fixable driver.

Whether you’re managing vendors in India, negotiating in the GCC, or sourcing globally, better data = better decisions = lower costs.

Want to see what clean data can do for your procurement strategy? Book a demo of our Data Management platform today.