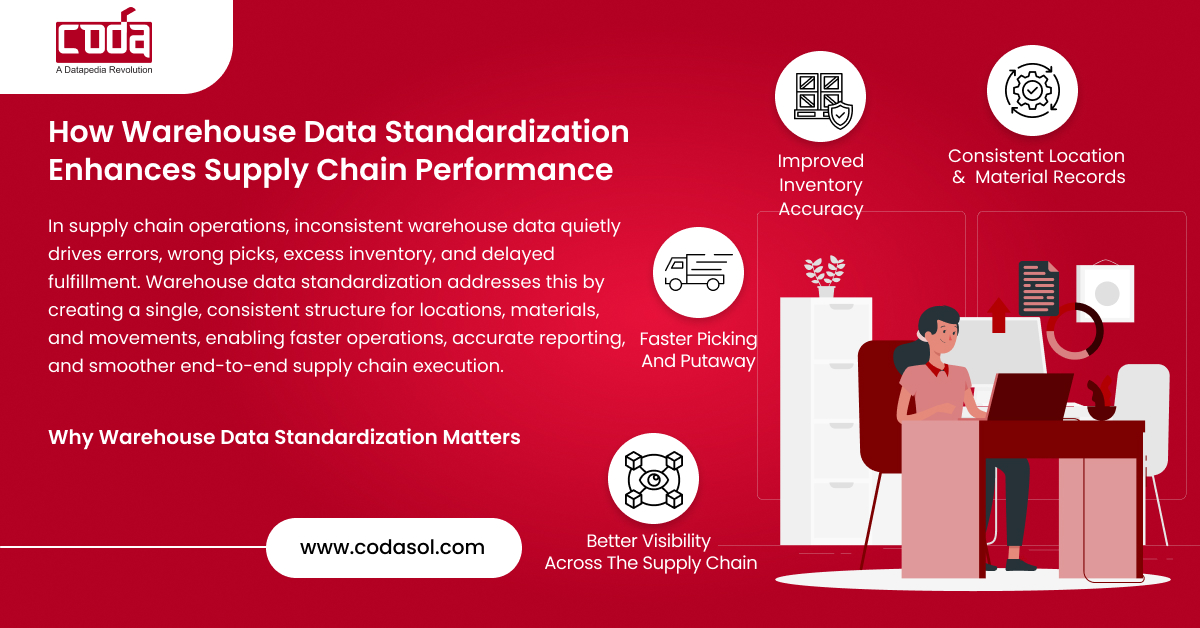

How Warehouse Data Standardization Enhances Supply Chain Performance

If you’re dealing with inaccurate inventory, delayed shipments, mismatched SKUs, or constant coordination issues between procurement, warehouse, and operations teams, the root cause is rarely people; it’s data. In asset-intensive supply chains, even a single incorrect item description or duplicate record can trigger costly errors across thousands of transactions.

The fastest way to eliminate these inefficiencies is through warehouse data standardization, supported by a strong Master Data Management (MDM) foundation. It creates consistency at the source, so every downstream process runs on clean, trusted data.

What Is Warehouse Data Standardization?

Warehouse data standardization means creating consistent, accurate, and uniform master data across all warehouse, supply chain, and operational systems. It ensures that every item, from a gasket to a chemical barrel to a valve assembly, is defined, classified, described, and managed in one consistent way across the entire organization. When master data is governed from the start, improvements go beyond clean records into real operational gains such as better space utilization, higher picking accuracy, and stronger inventory control.

In practice, warehouse data standardization includes:

- Standard naming conventions

- Unified product descriptions

- Harmonized units of measure

- Consistent product attributes

- Standard classification (like ECLASS)

- Harmonized supplier and manufacturer data

- Clean, validated item master records

- A governed process for changes and updates

Combined with a modern MDM platform, it creates a single source of truth that all systems, ERP, WMS, TMS, CMMS, procurement, and analytics rely on.

How Warehouse Data Standardization Improves Supply Chain Performance

1. Higher Accuracy & Fewer Errors Across the Supply Chain

In environments like Oil & Gas, Utilities, EPC, and Manufacturing, where technical attributes matter, even a tiny description mistake can lead to wrong material selection or safety risk. Standardized data prevents and reduces

- Duplicate item creation

- Mismatched descriptions

- Wrong supplier linkages

- Incorrect units of measure

- Inconsistent specifications

This leads to fewer mispicks, fewer returns, fewer blocked invoices, and more confidence in every transaction from purchase requests to goods receipts.

2. Real-Time Visibility & Better Traceability

Whether you manage 5 or 50 warehouses, standardized data creates connected, transparent operations. Leaders gain the confidence to make fast decisions because the underlying data is trusted. When your warehouse data is standardized, systems can “talk to each other” cleanly and give supply chain leaders:

- Real-time inventory visibility across plants

- Clear mapping between spare parts and equipment

- Traceability across procurement, quality, and warehouse

- Accurate replenishment, demand planning, and forecasting

- Full stock visibility for shutdowns/turnarounds

3. Stronger Supply Chain Resilience & Lower Risk

In large-scale maintenance or emergency scenarios, having consistent, governed data ensures faster response and fewer delays. With standardized warehouse data, enterprises can:

- Conduct better supplier risk assessments

- Ensure item interchangeability across OEM and alternative suppliers

- Strengthen quality control and compliance

- Trace materials across supply chain disruptions

- Reduce dependency on single-source vendors

4. Better Decision-Making Through a Single Source of Truth

When leaders have accurate, unified warehouse data, analytics becomes reliable:

- Forecasting becomes more accurate

- Inventory planning becomes data-driven

- Demand spikes can be predicted

- Supplier performance becomes measurable

- Obsolete stock can be identified

- High-value spares can be optimized

This is where standardized warehouse data directly improves EBITDA by enabling better strategic and operational decisions.

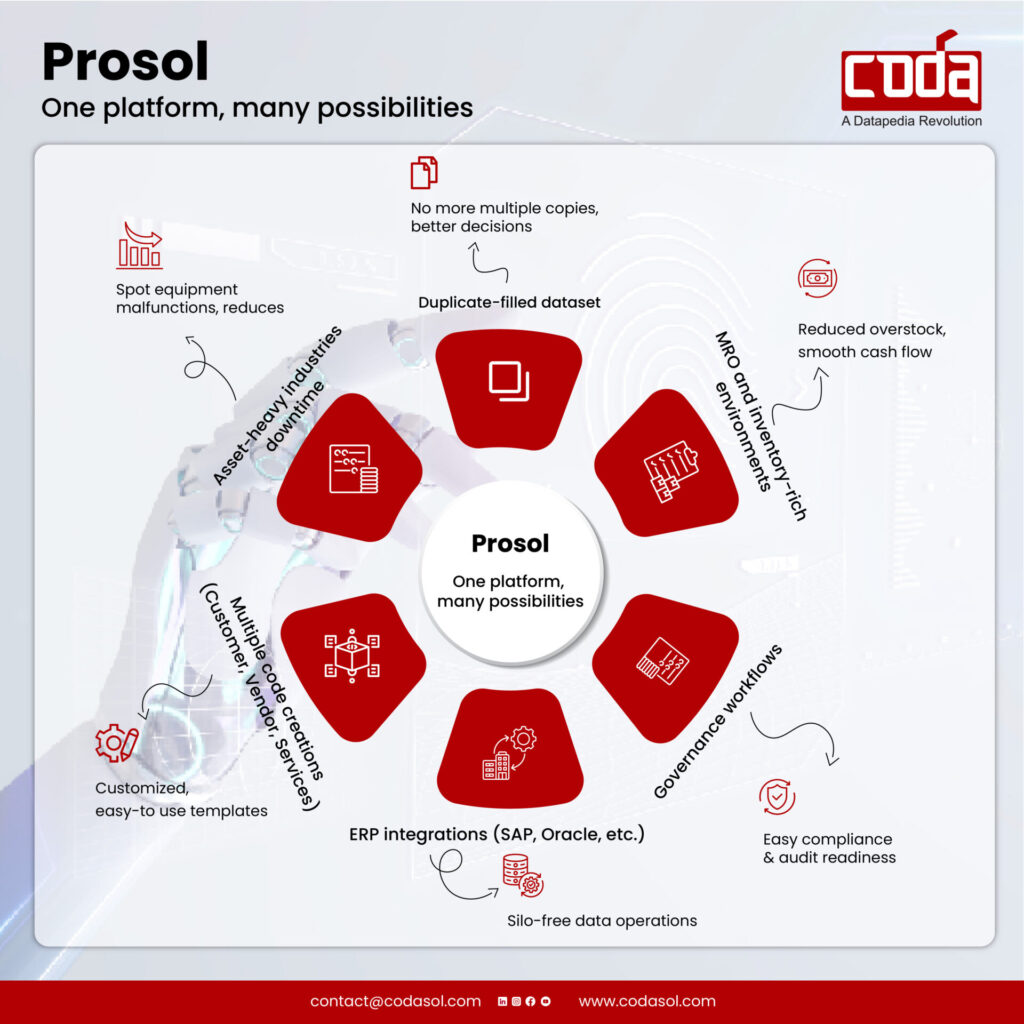

See how PROSOL standardizes warehouse data at scale, with clean, governed materials flowing seamlessly into ERP and WMS

Implementation Framework for Warehouse Data Standardization

1: Assessment & Governance Setup

- Audit all warehouse data sources

- Identify duplicates, inconsistencies, gaps

- Define naming conventions and attribute structures

- Establish governance roles (data owners, stewards)

- Build business rules for validation and approvals

- This phase sets strong foundations.

2: Data Standardization & MDM Integration

- Cleanse and harmonize existing warehouse data

- Map materials to standards like ECLASS

- Create the “golden record” for each item

- Integrate ERP, WMS, CMMS, procurement systems

- Ensure real-time or scheduled data synchronization

- This phase builds the single source of truth.

3: Continuous Monitoring & Improvement

- Automate data audits

- Track data quality KPIs

- Conduct periodic cleansing cycles

- Expand to additional domains (supplier, vendor, asset, location)

- Refine business rules as warehouse operations evolve

- This ensures data quality stays high over the long term.

How MDM Connects Warehouse Data with ERP and Operational Systems

Warehouse data standardization delivers full value only when it is tightly connected to ERP, WMS, and maintenance systems. This is where MDM becomes the control layer governing data before it enters operational platforms.

Instead of allowing inconsistent or duplicate records into core systems, MDM validates, standardizes, and approves material and supplier data at creation. Only clean, governed records flow into ERP and downstream warehouse systems, ensuring every transaction from procurement and receiving to picking, maintenance, and billing runs on trusted data.

With MDM in place, standardized warehouse data moves seamlessly across:

- ERP for procurement, finance, and inventory control

- WMS for picking, put-away, and bin management

- CMMS/EAM for spare parts and maintenance planning

- Analytics for forecasting and performance monitoring

This system-led governance removes data drift, prevents errors at the source, and keeps warehouse operations reliable as scale and complexity grow.

Warehouse Data Standardization Before vs After

| Metric | Before Standardization | After Standardization |

|---|---|---|

| Data accuracy | Low, inconsistent fields | High; governed & validated |

| Inventory visibility | Fragmented & siloed | Real-time, unified |

| Procurement errors | Frequent | Reduced significantly |

| Stock levels | High overstock, shortages | Optimized & predictable |

| Warehouse efficiency | Manual, slow | Automated, streamlined |

| Supplier alignment | Poor linkage | Clean, consistent mapping |

| Decision-making | Risky, unreliable | Data-driven & confident |

See how standardized warehouse data can reveal hidden cost savings across your supply chain.

Common Challenges and How to Avoid Them

1. Unclear Data Ownership

Fix: Assign data stewards, define approval workflows, and enforce governance.

2. Legacy Systems and Integration Issues

Fix: Integrate gradually, starting with critical domains, using a modern MDM platform with ready connectors.

3. Change Resistance from Warehouse Teams

Fix: Provide training, communicate ROI, and involve operations early.

4. Poorly Defined Standards

Fix: Use proven frameworks like ECLASS and global classification norms.

Frequently Asked Questions

1. Why is warehouse data standardization important for supply chain performance?

Because inconsistent data creates errors, delays, and increased costs. Standardization ensures accuracy, visibility, and reliable decision-making.

2. How does MDM improve warehouse inventory accuracy?

It provides one golden record for each item with clean descriptions, attributes, and classifications, ensuring all systems use the same, correct data.

3. What standards should companies follow?

Many enterprises adopt ECLASS for product classification and GDSN for global product data synchronization.

4. How long does a warehouse data standardization project take?

Most enterprises complete initial phases in a few months, with continuous improvement afterward.

5. What are the risks of not standardizing warehouse data?

Higher operational cost, inventory inaccuracy, procurement mistakes, equipment downtime, supplier risk, and poor planning.

Ready to transform your supply chain with accurate, standardized warehouse data?